US Steel Corporation

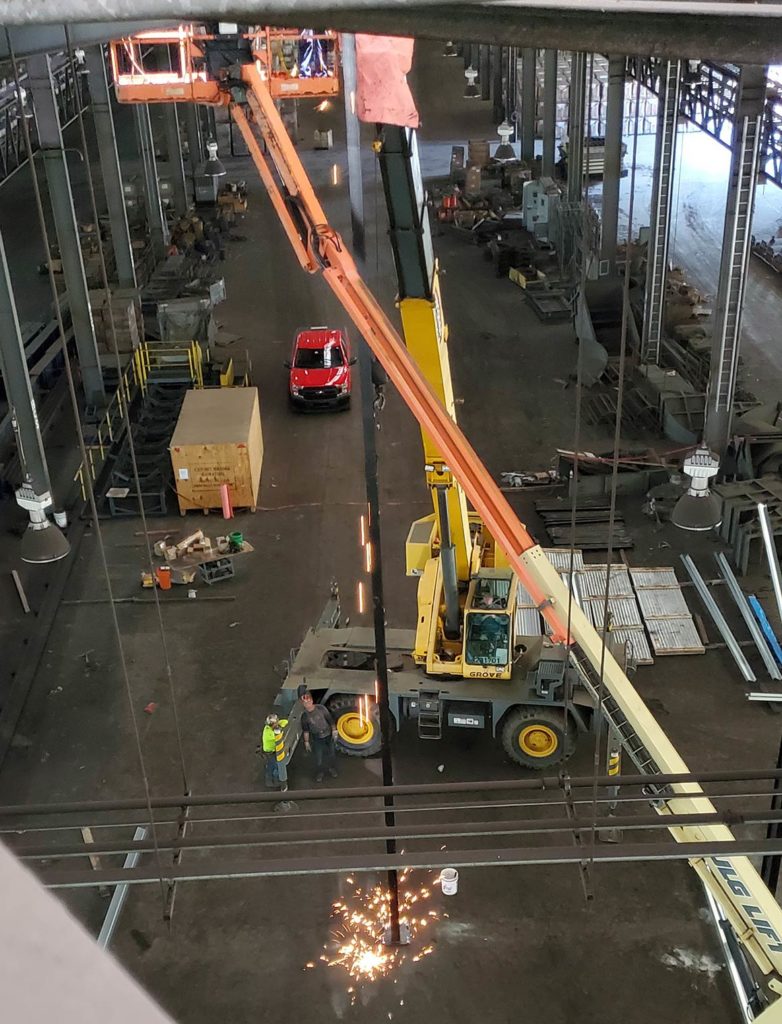

Since 1901, US Steel has served as a leading steel manufacturer and innovator. Superior Construction has performed work at various US Steel facilities since the 1950s — most notably at the Midwest and Gary Works plants, with the latter being the largest integrated mill in North America — in order to keep the plants and their systems operational.

- Routine downturn mechanical maintenance

- Structural steel and building repairs

- Concrete foundation installation and repair

- Environmental remediation

- Overhead crane repair and rail replacements

- Mechanical repairs to pneumatic and hydraulic equipment

- Various outages, emergency callouts, and standard scheduled work

Ongoing

Various Zero Recordable Injury Awards, National Maintenance Agreement Policy Committee

The Work

Most recently, Superior’s focus is on the hot strip mill, caster, pickle line, galvanizing line, Q-BOP, No. 1 BOP, and coke plant. Our work at these facilities varies from capital improvement projects to routine maintenance, scheduled area outages, and emergency call outs. Our industrial / petrochemical division completes projects that focus on our strengths in heavy civil, structural, and mechanical construction.

Our self-performed operations consist of excavation, stormwater mitigation, earth retention, pile driving, concrete foundations, floor repairs and paving, cementitious and epoxy grouting, structural steel erection and field fabrication, mechanical equipment replacement / maintenance, precision leveling and alignment, pre-engineering building erection, and overhead crane maintenance / repairs. Our services also include multi-craft around-the-clock outage executions involving civil, structural, and complex mechanical work lasting anywhere from one day to several weeks.

The Results

Superior regularly partners with US Steel’s engineering department to assist in constructability reviews — planning that enables them to minimize operational disruptions during routine maintenance work, outages, and emergencies. We also help them optimize cost efficiencies. Our strong and long-lasting partnership contributes to reliable and smooth operations at the Gary Works plant, which upholds an annual raw steelmaking capability of 7.5 million net tons.