The Client

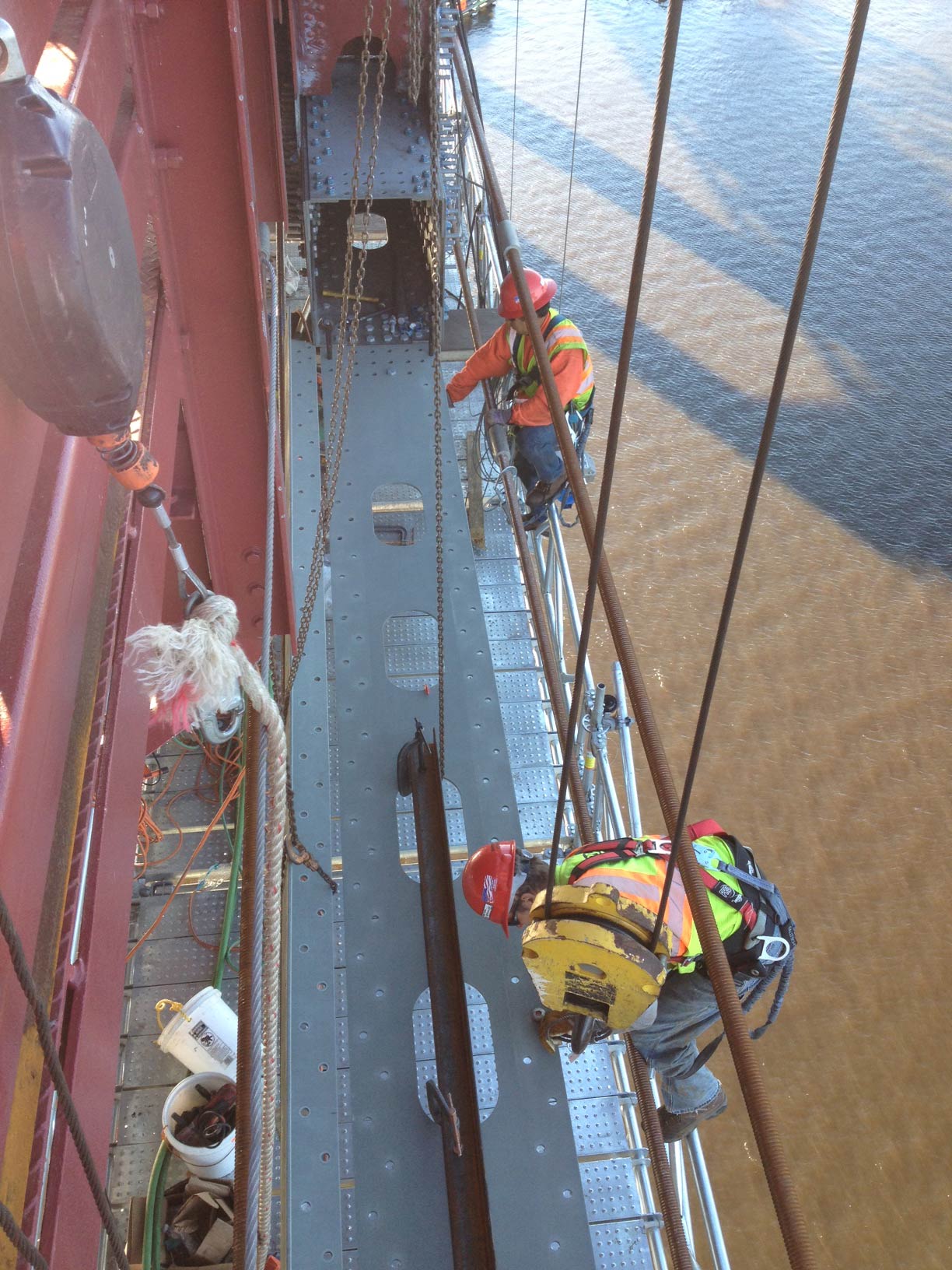

When a ship struck Florida’s Mathews Bridge in 2013, a critical chord in the steel structure was severed — making collapse imminent for a major thoroughfare that carries about 56,000 vehicles a day. Our team of construction professionals worked in tandem with nearly 200 other experts on this unprecedented emergency repair project for the Florida Department of Transportation.

Project Fast Facts

- Client: Florida Department of Transportation; Mathews Bridge

- Location: Jacksonville, FL

- Work Performed: Emergency repairs included jacking system, removal and replacement of the connection plate, stub beam installation, new lower chord member installation, cheese place and gusset installation, and final load transfer.

- Project Schedule: 34 days (completed 12 days ahead of schedule)

- Completion Date: October 29, 2013