The Client

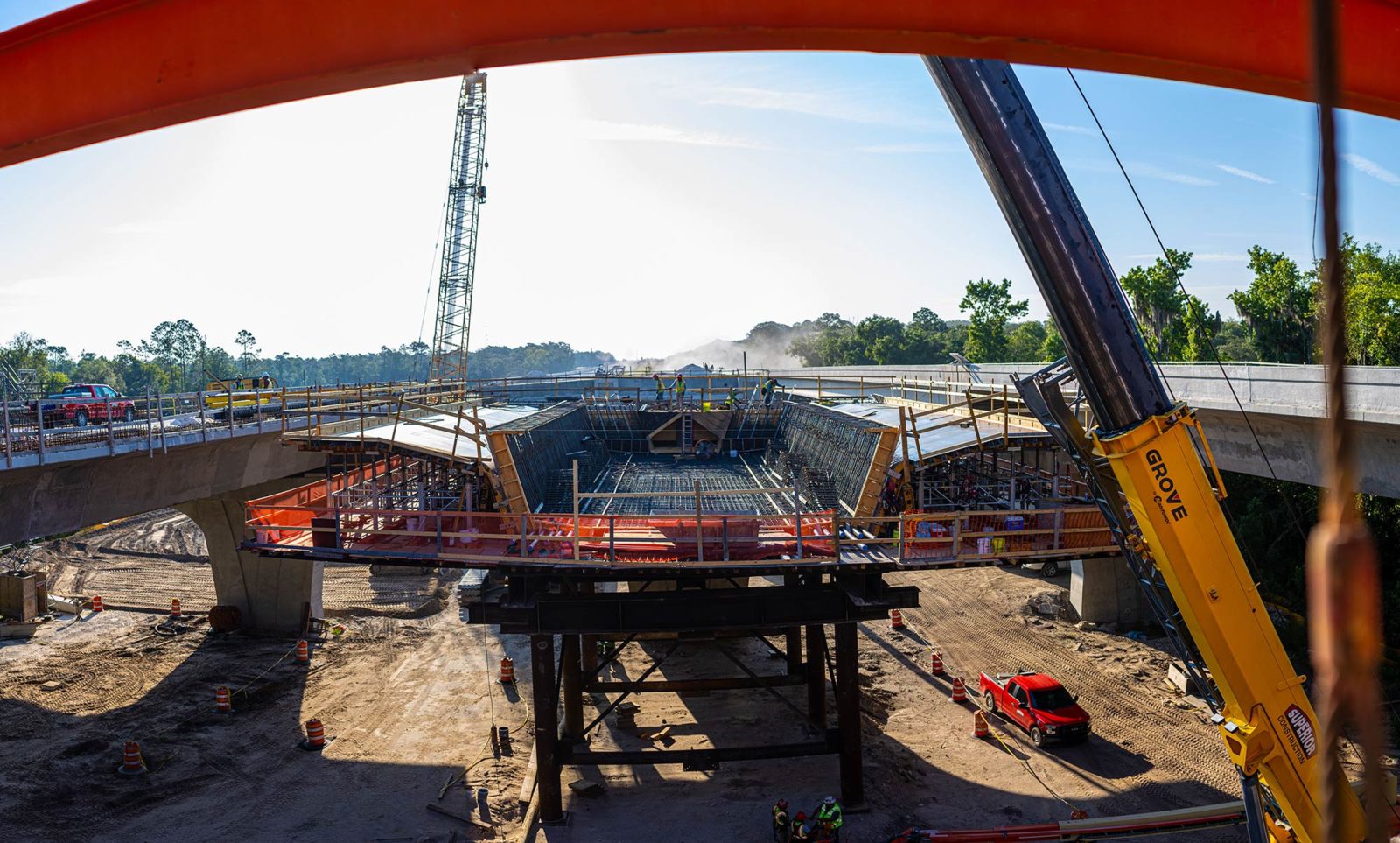

The Wekiva Parkway (SR 429) connects to SR 417, completing the beltway around Central Florida, while helping to protect the natural resources surrounding the Wekiva River. The Florida Department of Transportation (FDOT) hired the Superior Construction design-build team to complete section six of eight sections total, which consists of nearly six miles of limited access toll road that is largely elevated along the existing SR 46 corridor. The design-build project includes 18 bridges, three of which are a key portion of the project — segmental bridges over the Wekiva River.

Project Fast Facts

- Client: Florida Department of Transportation (FDOT)

- Location: Seminole County, Florida

- Work Performed: 18 bridges: three cast-in-place segmental box bridges, six conventional, and nine wildlife crossings; a parallel service road; new pavement construction; widening, milling and resurfacing; drainage system improvements; intelligent transportation system (ITS); signing and pavement markings; utility coordination; tolling infrastructure; landscape concept development; and extensive stakeholder coordination

- Project Schedule: 5 years

- Completion Date: Summer 2022